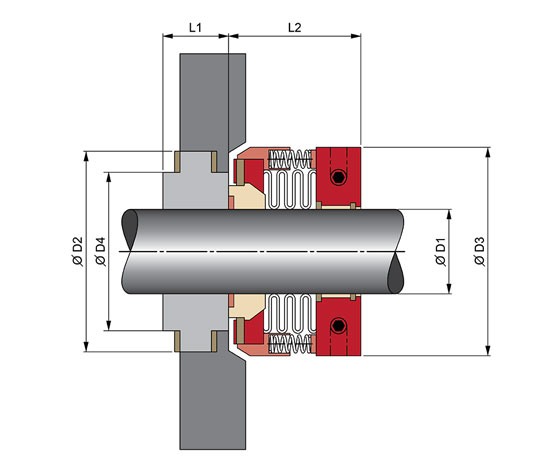

DS-710

Suitable for a wide range of services conditions.

Application

- For use with extremely corrosive chemicals, including concentrated acids and salts, strong oxidizing and reducing agents, and chemically active organic compounds.

- For external mounting in pumps and agitators vessels.

The DS-710 seal has a replaceable face insert, so that different face materials can be used to

handle a wide range of corrosive and abrasive liquids. The DS-710 seal face is integral with the composite PTFE bellows.

Operating Conditions

- Max. Operating Pressure : 12 kg/cm 2 *

- Temperature Range : -50 to 250 *

- Max. Rubbing Speed : 25 m/s

*(Depend on combination of materials)

Design Features/Benefits

- Mounted outside the seal chamber with only the internal surfaces of the secondary seals and face in contact with the process liquid.

- Maximum corrosive resistance, longlife operation.

- Multiple springs exert even closing force on seal faces. Ensure even loading of seal face and compensates for acceptable shaft misalignment.